LQG type three-screw asphalt pump

The salient features of the LQG three-screw asphalt pump are its simple structure, low pressure pulsation, stable flow, reliable work balance, high rotation speed, low noise, high efficiency, long life, and self-priming capability.

Product Usage

The three-screw pump is suitable for the transportation of lubricating oils and lubricious liquids of fuel oils, lubricating oils, hydraulic oils, crude oil, bitumen and other similar oils. Lubricating pumps in the industrial sector, hydraulic pumps in the hydraulic system, conveying and booster pumps in the fuel system, and conveying and refueling pumps in the oil system. The distinctive feature of the LQG three-screw asphalt pump is its simple structure. , Low pressure pulsation, stable flow, reliable working balance, high rotation speed, low noise, high efficiency, long life, self-priming ability.

Model number sense

For example: LQG90×2-46 LQG-three-screw asphalt pump 90×2-46 - specifications (outer diameter, pitch number, helix angle)

Performance parameters

| Model number |

Flow m3/h |

Pump outlet pressure Mpa |

Pump speed y/min |

Suction vacuum m (meter column) |

Import mm | Outlet mm |

Motor Model Power (kw) |

Liquid viscosity mm2/sec |

Medium temperature °C |

Transportation distance m |

| 100×2-46 | 72 | 1 | 1440 | 0.95 | 125 | 125 | y180L-4 22 | 3250 | 350 | 100 |

| 100×2-46 | 72 | 0.6 | 1440 | 0.95 | 125 | 125 | y180L-4 18.5 | 3250 | 350 | 80 |

| 100×2-46 | 48 | 0.8 | 970 | 0.95 | 125 | 125 | y180L-6 15 | 4300 | 350 | 80 |

| 90×2-46 | 52.5 | 1 | 1440 | 0.95 | 100 | 100 | y180L-4 18.5 | 3250 | 350 | 100 |

| 90×2-46 | 52.5 | 0.6 | 1440 | 0.95 | 100 | 100 | y160L-4 15 | 3250 | 350 | 80 |

| 90×2-46 | 34 | 0.8 | 970 | 0.95 | 100 | 100 | y160L-6 11 | 4300 | 350 | 80 |

| 80×2-46 | 25 | 1 | 1440 | 0.95 | 80 | 65 | y160L-4 11 | 3250 | 350 | 100 |

| 80×2-46 | 25 | 0.6 | 1440 | 0.95 | 80 | 65 | y132L-4 7.5 | 3250 | 350 | 80 |

| 80×2-46 | 17 | 0.8 | 970 | 0.95 | 80 | 65 | y160L-6 7.5 | 4300 | 350 | 80 |

| 54×2-46 | 14 | 4 | 1440 | 0.95 | 50 | 50 | y132L-4 5.5 | 3250 | 350 | 100 |

| 54×2-46 | 14 | 0.6 | 1440 | 0.95 | 50 | 50 | y112L-4 4 | 3250 | 350 | 80 |

| 54×2-46 | 8 | 1 | 970 | 0.95 | 50 | 50 | y132L-6 3 | 4300 | 350 | 100 |

| 54×2-46 | 8 | 0.8 | 970 | 0.95 | 50 | 50 | y112L-6 2.2 | 4300 | 350 |

|

Corrosion resistance of main materials for pumps (for reference)

| medium |

Concentration (%) |

Polypropylene |

Concentration (%) |

ABC | ||

| 25°C | 50°C | 20°C | 60°C | |||

| sulfuric acid | 60 | √ | <30 | √ | Χ | |

| Nitric acid | 25 | √ | 20 | √ | Ο | |

| hydrochloric acid | <36 | √ | <38 | √ | √ | |

| Hydrofluoric acid | 35 | √ | 40 | √ | Χ | |

| acetic acid | <80 | √ | <20 | √ | Ο | |

| Sodium hydroxide | 100 | √ | √ | √ | ||

| Potassium dichromate | 25 | √ | √ | √ | ||

| Smelly water | Χ | Ο | Χ | |||

| Ethanol | √ | <50 | √ | √ | ||

| acetone | √ | 10 | Ο | |||

| Tetrachloroethane | Ο | Ο | Χ | |||

| Freon 22 | √ | Ο | Ο | |||

| Bleach | CL13% | √ | CL12.5% | Ο | Ο | |

| Plating solution | √ | Ο | Χ | |||

| Photographic solution | √ | √ | √ | |||

| medium |

Concentration (%) |

stainless steel |

Concentration (%) |

ceramics | ||

| 25°C | 50°C | 25°C | 50°C | |||

| sulfuric acid | <5 | √ | Χ | △ | △ | |

| Nitric acid | 70 | △ | √ | △ | △ | |

| hydrochloric acid | Χ | △ | △ | |||

| Hydrofluoric acid | Χ | 0~100 | Χ | |||

| acetic acid | <20 | √ | √ | △ | △ | |

| Sodium hydroxide | 70 | √ | √ | Ο | Χ | |

| Potassium dichromate | 40 to 60 | △ | △ | 10 to 20 | △ | △ |

| Smelly water | Ο | △ | △ | |||

| Ethanol | △ | √ | △ | △ | ||

| acetone | △ | △ | △ | |||

| Tetrachloroethane | 50 | △ | △ | △ | △ | |

| Freon 22 | △ | △ | △ | |||

| Bleach | CL12% | Χ | △ | △ | ||

| Plating solution | △ | △ | ||||

| Photographic solution | △ | △ | △ | |||

Note: △ is excellent; √ is good; Ο is available, but there is obvious corrosion; Χ severe corrosion, not applicable.

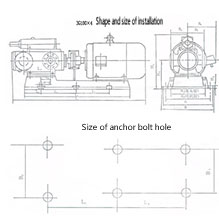

| Pump model | cabin seat no | L1 L2 L3 L4 L5 L6 L7 | B1 B2 B3 B4 | H1 H2 H3 H3 | Nd | D1×G1 | D2×G2 |

| 30×4 |

80 90S 90L 100L |

665 383 95 35 82 138 ... 703 393 95 40 87 138 ... 729 393 95 40 87 138 ... 654 383 95 35 82 138 ... |

250 210 160 155 250 210 160 180 250 210 160 190 250 210 160 155 |

274 140 45 274 140 45 274 140 45 274 140 45 |

4-Ø14 4-Ø14 4-Ø14 4-Ø14 |

Ø32x44Ø Ø32x44Ø Ø32x44Ø Ø32x44Ø |

Ø25x34Ø Ø25x34Ø Ø25x34Ø Ø25x34Ø |

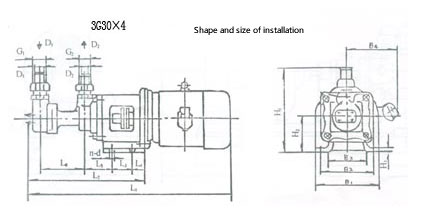

| 25×4 |

80 90S 90L 100L |

538 340 200 70 29 125 95.5 608 380 250 65 26 125 90.5 633 380 250 65 29 125 90.5 637 415 265 75 29 125 101.5 |

280 240 240 150 280 240 240 160 280 240 240 160 305 265 265 180 |

255 160 20 265 160 20 265 160 20 315 170 20 |

4-Ø15 4-Ø15 4-Ø15 4-Ø15 |

Ø25x34Ø Ø25x34Ø Ø25x34Ø Ø25x34Ø |

Ø20x34Ø Ø20x34Ø Ø20x34Ø Ø20x34Ø |

| 36×4 |

100L 112M 132S |

770 438 298 70 44 168 112 790 438 298 70 44 168 117 865 518 368 75 44 168 117 |

330 290 290 180 350 310 310 190 380 340 340 210 |

337 192 20 345 192 20 375 192 20 |

4-Ø19 4-Ø19 4-Ø19 |

Ø50x59Ø Ø50x59Ø Ø50x59Ø |

Ø40x50Ø Ø40x50Ø Ø40x50Ø |

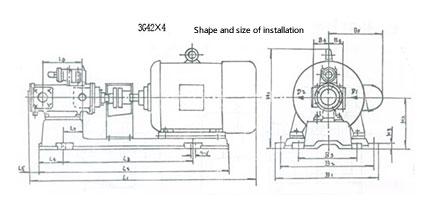

| Pump model | cabin seat no | L1 L2 L3 L4 L5 L6 L7 | B1 B2 B3 B4 B5 | H1 H2 H3 | Nd |

| 42×4 |

112M 132S 160M |

840 725 420 150 41 158 50 917 765 460 150 41 158 50 1043 890 590 150 41 158 50 |

410 350 270 88 190 450 390 270 88 210 480 420 270 88 265 |

343 190 35 385 202 35 455 230 35 |

4-Ø25 4-Ø25 4-Ø25 |

| Pump model | D1 F1 G1×G1 n1-M1 | D2 F2 G2×G2 n2-M2 |

| 42×4 | Ø65 Ø130 128x128 4-M12 | Ø40 Ø108 118x118 4-M16 |

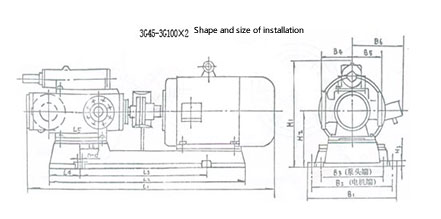

| Pump model | cabin seat no | L1 L2 L3 L4 L5 L6 | B1 B2 B3 B4 B5 B6 | H1 H2 H3 | Nd |

| 45×4 |

Y100L Y132S Y132M Y160M |

890 740 472 145 209 85 985 809 518 145 209 85 1025 838 538 145 209 85 1119 932 610160 209 73.5 |

325 285 285 130 140 180 380 340 340 130 140 210 380 340 340 130 140 210 429 389 340 130 140 265 |

350 205 25 400 217 25 400 217 25 470 245 25 |

4xØ18 4xØ18 4xØ18 4xØ18 |

| 60×4 |

Y160M Y160L Y120L |

1297 1017 700 178 285 100 1342 1061 700 178 285 100 1475 1157.5 757.5 183 285 100 |

460 410 370 170 175 265 460 410 370 170 175 265 525 475 370 170 175 310 |

585 270 30 580 270 30 585 310 30 |

4xØ23 4xØ23 4xØ23 |

| 70×2 |

Y132M Y160M |

1199 930 587 159 165 71 1289 1012 652 160 165 71 |

420 380 380 170 170 210 465 425 380 170 170 265 |

485 275 30 500 275 30 |

4xØ23 4xØ23 |

| 70×4 |

Y180M Y200L |

1404 1199 780.5 230.5 305 145 1509 1277 795 230.5 305 145 |

495 455 380 170 170 285 540 500 380 170 170 310 |

540 290 30 585 310 35 |

4xØ23 4xØ23 |

| 80×2 |

Y160M Y180M |

1244 1043 663 165 204 110 1308 1092 707 165 204 110 |

470 430 430 190 190 265 480 440 440 190 190 285 |

505 280 30 540 290 30 |

4xØ23 4xØ23 |

| 80×4 |

Y200L Y225M |

1570 1241 836 204 360 145 1640 1297 875 204 360 145 |

525 475 410 190 190 315 580 530 410 190 190 345 |

585 310 30 640 335 30 |

4xØ23 4xØ23 |

| 100×2 |

Y180L Y225S |

1513 1265 821 195 254 140 1623 1336 865 195 254 140 |

520 460 460 220 220 285 595 535 460 220 220 345 |

580 330 30 640 335 30 |

4xØ27 4xØ27 |

Import and export flange size

| Pump model | D1 E1 F1 G1 n1-d1 | D2 E2 F2 G2 n2-d2 |

| 45×4 | Ø65 Ø110 Ø130 Ø160 4-Ø13.5 | Ø50 Ø102 Ø125 Ø165 4-Ø17.5 |

| 60×4 | Ø100 Ø148 Ø170 Ø210 4-Ø17.5 | Ø65 Ø122 Ø145 Ø185 8-Ø17.5 |

| 70×2 | Ø100 Ø140 Ø170 Ø205 8-Ø18 | Ø65 Ø120 Ø145 Ø180 8-Ø18 |

| 70×4 | Ø100 Ø140 Ø170 Ø205 8-Ø18 | Ø65 Ø120 Ø145 Ø180 8-Ø18 |

| 80×2 | Ø125 Ø175 Ø200 Ø235 8-Ø18 | Ø80 Ø135 Ø160 Ø195 8-Ø18 |

| 80×4 | Ø125 Ø175 Ø200 Ø235 8-Ø18 | Ø80 Ø135 Ø160 Ø195 8-Ø18 |

| 100×2 | Ø150 Ø215 Ø240 Ø275 8-Ø18 | Ø100 Ø170 Ø200 Ø235 8-Ø18 |

| 100×4 | Ø150 Ø215 Ø240 Ø275 8-Ø18 | Ø100 Ø170 Ø200 Ø235 8-Ø18 |

| Pump model | cabin seat no | L1 L2 L3 L4 L5 L6 L7 | B B1 B2 B3 B4 B5 B6 | H1 H2 H3 | Nd |

| 100×4 |

Y250M-4 Y280S-4 |

1993 1590 506 507 262 233 444 2043 1658 548 549 262 233 444 |

650 520 590 460 220 220 385 705 520 645 460 220 220 410 |

685 360 30 750 390 30 |

6-Ø27 6-Ø27 |

No.31011802002466

No.31011802002466