National standard floating ball valve

Main material: carbon steel, stainless steel

Nominal diameter: DN15 ~ 200mm

Pressure range: PN1.0 ~ 10.0MPa

Working temperature: -29 ℃ ~ + 200 ℃

Application : Applicable to the switching of medium flow and the diversion or mixing of fluids to mediums in pipeline systems such as water supply, petrochemical, metallurgy, mining, textile, energy, papermaking, food, and steel.

The working principle is to make the valve open or blocked by rotating the valve stem. Ball valve switch is light, small size, can be made of a large diameter, reliable sealing, simple structure, easy maintenance, sealing surface and spherical surface often in the closed state, not easily eroded by the media, widely used in various industries.

The national standard floating ball valve only needs to be closed tightly with a 90-degree rotation operation and a small rotational torque. The completely equal valve body cavity provides a small, straight flow path for the medium. It is generally considered that ball valves are most suitable for opening and closing directly, but recent developments have designed the ball valve to be used for throttling and controlling flow. The main characteristics of the ball valve are its compact structure, easy operation and maintenance, suitable for general working media such as water, solvent, acid and natural gas, and also suitable for working medium with poor working conditions such as oxygen peroxide, methane and ethylene. The ball valve body can be integral or modular. This type of valve should be installed in the horizontal direction of the pipeline.

National standard floating ball test pressure

|

Pressure Level |

Test pressure (Mpa) | |

|

Nominal pressure (PN) |

Shell test |

Seal test |

| 1.0 | 1.5 | 1.1 |

| 1.6 | 2.5 | 1.76 |

| 2.5 | 3.8 | 2.75 |

| 4.0 | 6.0 | 4.4 |

| 6.4 | 9.6 | 7.04 |

|

16.0 |

3.0 | 2.2 |

| - | 7.6 | 5.6 |

| - | 15.0 | 11.0 |

| - | 2.4 | 1.5 |

| - | 5.8 | 4.0 |

National standard floating ball valve specification

|

Design Basis |

GB series |

|

design standards |

GB/T12237 |

|

Flange connection structure length |

GB/T12221 |

|

Structure length (welding) |

GB/T15188.1 |

|

Connection flange |

GB/T9113, JB/T79, Hg20592 |

|

Butt welding end |

GB/T12224 |

|

Test and inspection |

GB/T9092 |

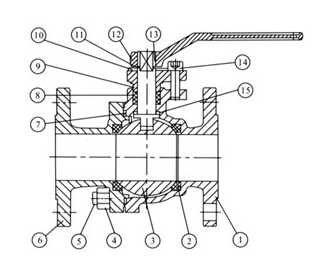

National standard floating ball valve main parts and materials

| No. |

Part Name |

Materials | |

| GB | ASTM | ||

| 1 | Body | WCB | A216-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1Cr18Ni9Ti | SS304 |

| 4 | Nuts | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | Right body | WCB | A216-WCB |

| 7 | Gasket |

Flexible graphite + stainless steel |

B12.10-304/FG |

| 8 | filler | PTFE | PTFE |

| 9 | Packing gland | WCB | A216-WCB |

| 10 | Positioning pieces | 25 | A105 |

| 11 | Retaining ring | 65Mn | AISI 1066 |

| 12 | handle | Kt33 | A47-667 Gr.32510 |

| 13 | Stem | 1Cr33 | A276-410 |

| 14 | Screws | 35 | A193-B7 |

| 15 | Thrust washer | PTFE | PTFE |

National standard floating ball valve features

1, floating ball valve lip seal valve seat, to ensure that the valve sealing performance is good, the friction coefficient is small, the operating torque is small.

2. Stem anti-flying structure: The stem is a bottom-mounted type to prevent pressure from flying out. At the same time, it can form metal contact with the valve body after the fire to ensure the stem seal.

3, fire anti-static device (soft seal floating ball valve).

4, with lock device. To prevent misoperation of the valve switch, there is a locking hole in the fully open and fully closed position of the valve to ensure that the valve is in the correct position.

5, floating ball valve is suitable for frequent operation, rapid opening and closing; relative small size, light weight, easy maintenance; not limited by the installation direction; fluid resistance, no vibration, low noise.

No.31011802002466

No.31011802002466